Steel Manufacturing Company overcomes ERP failure, transforming to digital excellence with Kinetech's agile custom software and system integration solutions. Learn how tech boosts sales and efficiency.

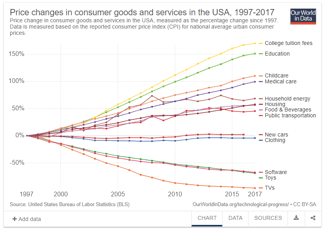

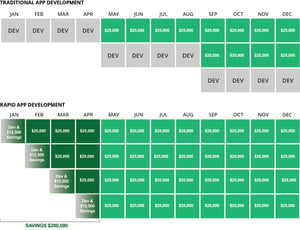

Most manufacturers face an impossible choice for software: rigid off-the-shelf solutions that force process changes, or custom development that takes 12-18 months with a 70% failure rate (Gartner, 2023).

A small group of manufacturers has discovered a third path—one that delivers custom fit at off-the-shelf speed.

This approach has proven successful across hundreds of manufacturing software implementations. Here, we examine two specific examples: an industrial manufacturer that digitized warehouse operations in 30 days and a steel processor that succeeded after two failed ERP implementations.

Both achieved what traditional approaches promise but rarely deliver: software perfectly aligned with their operations, delivered in weeks rather than years, without the risks that plague conventional projects.

The difference? They understood the COTS vs. custom dilemma is false. There's a third option that blends the best of both: the flexibility and perfect fit of custom development with the speed, cost-efficiency, and reduced risk of off-the-shelf systems.

This is how they did it—and how you can too.

An industrial integrated solutions manufacturer processed thousands of shipments daily, supporting large-scale projects in oil & gas, renewable energy, and industrial construction. Revenue was growing, project complexity was increasing, but their material management approach hadn't evolved past the scrappy methods that worked when they were half the size.

Their warehouse operations ran on improvisation: Sharpie markers on racks indicated material locations (when someone remembered to mark them). Project managers maintained their own Excel inventory trackers—none of which communicated with each other or with the ERP. Material movements were documented through email chains that created more confusion than clarity. The ERP showed what was purchased, but couldn't answer the only question that mattered: "Where is it right now?"

It worked—until it didn't.

When "Good Enough" Becomes Costly

The breaking point came during a critical project phase. Materials with a 12-week lead time couldn't be located. Procurement confirmed they'd been ordered, received, and logged in the ERP months ago. The warehouse team searched for hours. Had they been consumed by another project? Damaged and discarded? Simply lost in 200,000 square feet of racking?

The result: emergency reorders at premium pricing, project delays, difficult conversations with customers about missed milestones, and potential contract penalties. This scenario wasn't rare—it was routine.

Without real-time visibility into material location, status, and consumption, the organization faced compounding operational and financial risks:

Contract Exposure

Committed delivery dates are at risk because materials disappeared between receiving and production. With contracts often tied to customer project schedules—where delays cascade through entire construction timelines—missing materials created liability exposure far beyond the material cost itself.

Project Delays & Margin Erosion

Time spent searching for materials became a daily production bottleneck. Emergency procurement at premium pricing destroyed project margins. Worst case: delaying project starts because materials couldn't be confirmed as available, tying up working capital in projects that couldn't begin.

Warehouse Inefficiency

Uncertainty about existing stock led to over-ordering and excess inventory—stressing warehouse capacity and tying up capital. Warehouse staff spent hours daily searching for materials that the ERP claimed were on-hand. Physical inventory counts became dreaded, multi-day events that disrupted operations.

Procurement Planning Failures

Strategic purchasing decisions depend on accurate material counts. When you can't trust your inventory data, you can't optimize procurement timing, negotiate volume discounts, or plan working capital needs. The result: reactive procurement at higher costs instead of strategic planning.

The Scaling Problem

Most critically, as project volume increased and complexity grew, these manual workarounds would collapse under their own weight. The company was winning more business, but its operational infrastructure couldn't support the growth without significant risk.

The 30-Day Transformation

Kinetech's approach wasn't to replace what worked—it was to eliminate what didn't scale. Within 30 days, they delivered a mobile-first material management system that integrated with the existing ERP database and institutionalized the warehouse processes the team had developed over the years.

The solution captured materials at receiving with barcode scanning, tracked real-time location and consumption, and provided instant visibility across procurement, warehouse, and project management. No more Sharpies, Excel exports, or email chains about material movements.

The results were immediate:

The Cultural Shift

Perhaps most telling was the warehouse team's reaction. Initially skeptical of "another promise unlikely to deliver," they became the solution's strongest advocates after seeing a working prototype after just two weeks into development. Their question shifted from "Do we really need this?" to "When can we have it?"

Why? Because the system was built around how they actually worked—not how some consultant thought they should work.

Understanding Phantom Inventory

This manufacturer's story reflects a widespread challenge for many manufacturers: phantom inventory. Materials exist in the ERP—purchased, received, logged—but can't be located in the physical warehouse or on the shop floor.

Phantom inventory isn't just an accounting problem. It's lost money: production delays that miss committed dates, emergency procurement at premium pricing, customer satisfaction risk, competitive disadvantage in markets where delivery reliability separates market leaders from everyone else, and working capital tied up in materials you can't actually use.

For manufacturers operating on tight project margins, phantom inventory can be the difference between profitable growth and chaotic scaling that destroys value.

The Path Forward

The question isn't whether manual material tracking can work—clearly, it can for a time. The question is whether it can scale with your ambitions. For this manufacturer, the answer was no. Thirty days and one custom application later, they eliminated a constraint that would have limited their growth for years.

The True Business Impact

Based on our analysis of mid-market manufacturers who have not adopted a Smart Warehousing solution:

| Hidden Cost Category | Annual Business Impact |

|---|---|

| Project Risk Exposure | $1M–$50M+ per delayed project |

| Customer Relationship Risk | $500M+ in long-term partnership value |

| Phantom Inventory | $500K–$1M (duplicate purchases of existing stock) |

| Emergency Procurement | 300–500% rushed freight costs |

| Contract Penalties | 5–15% of contract value |

| Warehouse Space Constraints | $500K–$2M+ for facility expansion |

| Insurance & Carrying Costs | $50K–$200K on excess inventory |

| Inefficient Labor Allocation | $200K–$400K in unnecessary headcount |

| Suboptimal Purchasing | 10–25% procurement cost inflation |

| Competitive Disadvantage | Immeasurable lost opportunities |

When Strong Operations Are Held Hostage by Failing Software

The warehouse transformation story showed how we introduced technology where none existed—digitizing manual processes using our library of prebuilt components. But many manufacturers face a different challenge: they already have software running their operations, it's failing them, and every attempt to replace it has made things worse.

This is where a steel processing company found itself. They didn't need to digitize manual processes—they needed to replace a dying ERP system that had served them for decades. But two attempts at "big box" ERP implementations had both failed spectacularly, leaving them trapped: running on unsupported legacy software and losing faith that any replacement could work.

Unlike the warehouse digitization project where we started fresh with mobile apps and barcode scanning, this required replacing core production management software that ran their entire steel processing operation—and doing it after two expensive failures had created organizational trauma around any new technology initiative.

Their business was thriving: strong revenue growth, 30+ years of steel-processing expertise, and a loyal customer base. Their problem? The software keeping them operational was failing, and the "proven" enterprise solutions that promised to replace it couldn't handle their operations.

The Original System Reaches End-of-Life

Their customized Infor SyteLine installation had survived well (enough) for decades, but reached end-of-life. Vendor support was ending. Security vulnerabilities would pile up. Future versions couldn't support the customizations that ran their steel processing operations—workflows refined through years of expertise, integrations connecting production to inventory and shipping, custom reporting that drove daily decisions.

They needed a replacement. What followed were two costly failures.

First Failure: Microsoft Dynamics

First, they implemented Microsoft Dynamics for Manufacturing with professional vendor customization. Proven platform. Experienced implementation partner. Backing of Microsoft. The "safe" choice.

The implementation went live. Operations immediately suffered. The system couldn't accommodate their unique steel-processing workflow.

After months of struggle, they faced the painful reality: they needed to revert to their legacy SyteLine system—the very system they'd implemented Dynamics to replace.

The reversion was costly and disruptive. Data had to be migrated back. Processes had to be re-established. Staff had to be retrained on the old system. And everyone knew this was temporary—SyteLine was still end-of-life, still losing vendor support, still a ticking time bomb.

They'd spent a year and a substantial budget to end up exactly where they started: running on dying software with no viable path forward.

Second Failure: Syteline Again

Back to the same sunset version of SyteLine they'd been trying to escape. Another reversion. More money lost. More organizational trauma.

Two implementations. One reversion to the same dying system. Money spent. Years lost. And after all that investment and organizational trauma, they were running on the exact same unsupported software they'd started with—a system that had already lost vendor support while they competed against manufacturers with modern infrastructure.

As their team described, "We experienced significant organizational trauma. We could not afford another failure."

The conclusion was clear: off-the-shelf ERP solutions would never fit their operations. But they still needed software that could.

The False Choice: COTS vs. Custom

The traditional software decision presents what seems like an impossible trade-off:

- Commercial Off-The-Shelf: Fast implementation promised, rigid processes delivered. Your proven operations must conform to someone else's generic workflows. For the steel processor, this meant two failed attempts to force their steel processing expertise into systems built for "manufacturing in general"—which is to say, not built for them at all.

-

Traditional High Code Custom Development: Perfect fit promised, but 12-18 month timelines, big budgets, and 70% failure rates delivered. You don't see working software until it's too late to change course. Most development teams don't understand manufacturing, so you get technically sound software that doesn't solve operational problems.

After experiencing both paths, manufacturers are left asking: "Is there any solution that actually works?"

The Best of Both Worlds

Both manufacturers discovered a third path with Kinetech: custom solutions built from proven pre-built components.

Not generic COTS forcing process changes. Not an 18-month ground-up development. Software built to your exact operations, delivered in weeks using battle-tested building blocks.

The warehouse solution fit the industrial manufacturer's material tracking because we built around their actual operations—using prebuilt components include barcode scanning and ERP integration that eliminated months of development.

The production system fit the steel processor's workflows because we preserved their expertise while replacing what didn't work—leveraging our component library for custom functionality without custom timelines.

Perfect fit. Rapid delivery. Zero compromise.

How We Ensure Solution Fit

The difference isn't just the technology—it's how solutions get built:

Start with working software, not requirements documents. Within days, not months, you see your operations running in actual software. This isn't a demo or mockup—it's a working prototype built with production-grade components from our library.

Build with your team, not for them. Your operational experts work directly with our developers throughout. When something doesn't fit, we adapt immediately—not after months of development based on misunderstood requirements.

Prove it before you commit. You see working software solving real operational problems before making full investment decisions. No more seven-figure gambles on 18-month projects.

Leverage what already works. Our library of prebuilt components—mobile interfaces, barcode scanning, ERP integrations, workflow engines, reporting frameworks—eliminates the 60-70% of development time spent building common functionality. We focus effort on what makes your operations unique.

The result? Custom software that fits your exact operations, delivered with the speed and reliability COTS promises but never delivers.

This is how both companies succeeded where traditional approaches failed. The question isn't "COTS or custom?"—it's "How do we build it?

Why Traditional Development Fails: The Broken Telephone Effect

There's a simple reason why most software projects fail—it starts with how requirements move through the organization, but it's compounded by technology that can't keep up with what you learn.

Traditional Development Chain: Business Need → Business Unit Leader → Business User → IT Manager → IT Business Analyst → Systems Architect → Developer → QA → Business Unit Leader → Business User

At each handoff, critical context disappears:

- Your warehouse manager knows materials from certain suppliers arrive damaged and need immediate flagging—but that detail gets summarized away as "receiving inspection".

- Your production scheduler understands that material priority depends on production urgency, not FIFO, but the requirement becomes "standard queue management".

- Your quality manager knows specific heat lots require special handling—but it's documented as generic "material tracking".

By the time developers build features, they're solving problems that don't exist while missing the problems that matter.

Result: 85% of requirements lost in translation. Software that technically meets specifications but fails operationally.

This isn't incompetence—it's what happens when the people building software never talk to the people who understand the operations, and the technology platform can't support rapid iteration when you discover what actually needs to change.

The Digital Translation Model: Technology That Enables Agile Collaboration

Kinetech eliminates the telephone effect through continuous iteration with immediate validation—but this only works when the technology platform can keep pace with what you're learning:

BUSINESS NEED → WORKING SOLUTION → REAL-TIME FEEDBACK → CONSULTANT-DEVELOPER → back to BUSINESS NEED

The process should look something like this:

.png?width=442&height=430&name=Group%20200%20(1).png)

The technology matters because it must enable this rapid cycle:

Without technology that facilitates rapid iteration, even direct collaboration fails—you'd still wait weeks for changes, making the agile cycle impossible.

"With Kinetech, you're talking directly to someone who understands your business AND can build the solution. But just as important—I'm using a platform that lets me turn your feedback into working software in hours, not weeks. No translation needed, and no technology bottlenecks.

- Kinetech Project Lead

Traditional developers working with traditional platforms face double barriers: they don't understand operations, and even if they did, their technology stack requires weeks to implement changes.

The Game-Changer: Consultant-Developer + Rapid Development Technology

Success requires both technologists who understand your business AND technology that enables them to act quickly on what they learn.

1. Speed Without Sacrificing Function

Kinetech Timeline: 30-90 days

Secret: Years of manufacturing expertise crystallized into proven delivery practices and pre-built, customizable components.

We don't start from scratch. Our component library includes warehouse management, inventory control, production tracking, quality systems, and connectors common across manufacturers—customized to support your unique operational needs.

The industrial manufacturer received v.1 of their warehouse solution in 30 days. The steel processor replaced two failed ERP implementations in weeks. Both got custom software that fits their exact operations—because we built from proven components, not blank screens.

2. Process Alignment

"We build software around your process—not the other way around."

- Ricky Volz, Partner

For manufacturers with established processes, this approach delivers:

- 100% solution fit without forcing suboptimal process or organizational changes

- Institutionalizes tribal knowledge to differentiate your operations

- Balances flexibility with standardization to enable scale

- Eliminates data silos through integrated solutions

- Future-proofs decisions today, tomorrow, and years later

The steel processor's 30-year processing expertise became their competitive advantage—embedded in software, not trapped in people's minds. The industrial manufacturer's material tracking workflows stayed intact while going digital.

Your proven processes are competitive advantages. We preserve them while eliminating their manual constraints.

3. The Consultant-Developer Advantage

Traditional firms separate business consulting from technical development. Kinetech's consultant-developers combine both:

- Business consulting backgrounds, not just technical skills

- Understand your operational problems at the floor level

- Build solutions in real-time during discussions

- Eliminate translation errors entirely—no "whisper down the lane"

- Use the #1 rapid app development platform (Gartner 2025)

As one of our project leads explains:

"My background is in manufacturing operations and consulting, not only software. I can solve that person's business problem, understand the business logic, and then immediately turn to my platform and develop a solution."

- Kyle Kunzer, Senior Architect

This is why the warehouse team became advocates in two weeks—they worked directly with someone who understood their operations and could implement their feedback the same day.

This is why the steel processor succeeded after two failures—consultant-architects who understood steel processing operations, not just software specifications.

Why 70% of Implementations Fail

The steel processor experienced this firsthand—twice. Here's what kills projects:

COTS Failures:

-

Off-the-shelf software is not flexible or adaptable to your actual needs

-

Misaligned expectations between decision makers and users

-

Forced process changes disrupt proven workflows, create resistance, destroys competitive advantages

-

Unknown limitations you won't discover until you're deep into implementation

Traditional Custom Development Failures

-

Misaligned expectations when what decision-makers want ≠ what users need ≠ what gets built

-

Technology-first approach ignores actual business needs as developers focus on features, not solutions

-

Disconnected business / developer feedback loop where business doesn't see working software until it's too late or expensive to change course

-

Poor change management: Users resist systems they didn't help create

Result: Millions spent, years lost, and you're back where you started—or worse.

The Kinetech Success Framework: How We Mitigate Each Risk

1. Iterative Development Eliminates "Big Bang" Risk

You see working software in days, not months. Test it. Use it. Change it. Before full commitment.

- Industrial manufacturer: Working warehouse prototype in 7 days—validated before building more.

- Steel processor: Production system tested alongside legacy—proven before cutover.

No seven-figure gamble on 18-month projects. Incremental validation at every step.

2. Prebuilt Components Reduce Technical Risk

Our component library represents thousands of hours of manufacturing software development—debugged, proven, production-tested.

- Mobile interfaces that work in industrial environments

- Barcode/RFID scanning that handles real-world conditions

- ERP integrations tested across multiple platforms

- Workflow engines that support manufacturing complexity

You're not beta testing our components. They're already working in other manufacturers' operations.

3. Business (Not IT) Driven Ensures Operational Fit

Solutions designed and built alongside operational teams, not mandated by IT based on vendor presentations.

- Warehouse solution: Built with warehouse team—they became advocates, not resistors

- Production system: Built with production managers who understand steel processing

4. Direct Collaboration Eliminates Translation Errors

Consultant-developers work directly with operations—no broken telephone effect.

Problems identified on the shop floor get solved in the software the same day. No 6 month old requirements documents that miss operational reality.

5. Adaptive Approach Handles Discovery

Manufacturing operations are complex. You won't know everything you need upfront—and that's okay.

Our platform enables real-time adjustments when you discover:

- "This workflow needs an exception for rush orders"

- "These materials require different handling"

Traditional platforms require change requests, specifications, development sprints. We make changes in hours during the same conversation.

6. Proven Execution Methodology

We've delivered hundreds of custom applications across nearly every use case you can think of.

- Expert Siemens & Mendix Partner certifications

- 10+ years rapid application development and manufacturing software focus

- Deep domain expertise in warehouse operations, production management, quality systems

You're not our first warehouse system. You're not our first production management solution. We know what works—and what doesn't.

The Bottom Line

We mitigate risk through:

- Early validation: See it working early and often

- Proven components: Build from tested building blocks, not scratch

- Direct collaboration: Eliminate translation errors entirely

- Iterative approach: Adjust as you learn, not after it's built

- Manufacturing expertise: We've done this before—successfully

Traditional approaches force you to bet everything on one outcome. Our approach lets you validate continuously, adjust immediately, and only commit when you know it works.

That's how we eliminate the 70% failure rate.

You Are an Ideal Fit If You Want:

AND You Are Frustrated That:

This Is Not for You If You Would Rather:

You're at a decision point. Here are your three paths forward:

Option 1: Status Quo - Stay on the Current Path

If you're running on manual paper based processes:

- Missing materials, phantom inventory, emergency reorders at premium pricing

- Warehouse searches, Excel tracking, email chains instead of digital systems

- Manual workarounds that work now but won't scale with growth

- Falling behind competitors with real-time visibility

The industrial manufacturer was here: operations "working" but constraints growing.

If you're trapped on failing legacy systems:

- Running on unsupported software that could fail at any moment

- Unable to modernize because every replacement attempt has failed

- Competing against manufacturers with modern infrastructure

- Organizational paralysis from past implementation trauma

The steel processor was here: back on sunset SyteLine after two failed replacements.

Option 2: Traditional Implementation - The "Safe" Big-Box Choice

- 12-18 month timeline with 70% probability of failure or significant disappointment

- Force-fit your operations: Abandon proven processes for vendor's generic "best practices"

- Expensive customization attempts that break with updates and still don't work right

- Unknown limitations discovered only after commitment

- Organizational trauma that creates lasting resistance to technology

- Sunk cost trap: Too far in to turn back, too broken to succeed

The steel processor tried this—twice. Microsoft Dynamics failed. Second ERP failed. Millions spent, years lost, reverted to the same dying system both times.

Option 3: The Kinetech Way - Custom Fit at COTS Speed

- 30-90 day delivery: Working software validated before full commitment

- Perfect process alignment: Built around your operations, not forced compromises

- Proven components: Battle-tested building blocks eliminate risk and development time

- Iterative validation: See it, test it, adjust it—before going all-in

- Operational expertise institutionalized: Competitive advantages embedded in software

The Reality Check

Status Quo feels safe because it's familiar—but it's quietly expensive:

- Emergency procurement costs and customer relationship risk (if running manual)

- Competitive disadvantage while stuck on dying systems (if trapped on legacy)

- Growth constraints that compound over time (both scenarios)

Traditional Implementation feels safe because "proven vendors" and "industry-standard platforms"—until you're reverting to what you tried to replace after spending millions.

The Kinetech Way delivers what traditional approaches promise but rarely deliver: custom fit without custom timelines, proven technology without forced compromises.

Your Competitors Are Making Their Choice Right Now

While you're evaluating options, manufacturers in your industry are on one of two paths:

Path 1: Falling Behind

- Struggling with ERP limitations or manual offline systems

- Managing workarounds while losing ground daily

- Attempting traditional implementations that take years and often fail

- Operating with software built around their proven processes

- Real-time visibility enabling faster, better decisions

- Digital infrastructure that scales with growth

The gap widens every quarter.

The Uncomfortable Truth

Choosing to wait, to evaluate longer, to hope things improve—that's choosing Path 1.

The industrial manufacturer chose transformation. 30 days later: 100% material traceability.

The steel processor chose to try differently after two failures. Weeks later: production software that actually fits.

Both were where you are now. Both chose action over status quo.

Which side of the competitive divide will you be on in 90 days?

.png)

Step 1. Executive Strategy Call (60 Minutes)

Direct access to consultant-architects, who will build your solution—not salespeople.

We'll Cover:

- Current operational challenges and business impact

- Process fit evaluation—do your needs match our approach?

- Solution scope and customization requirements

- Timeline and investment discussion

Outcome: Clear understanding if we're the right fit and what transformation looks like for your operation.

Step 2. Proof of Concept (1 Week)

See your exact process running in working software before committing.

You'll Get:

- Working application customized to your critical workflow

- Live demonstration with your operational team

- Real validation—not mockups or demos

- Confirmed transformation roadmap and investment

Outcome: Confidence that the solution fits your operations, validated by the people who will use it.

Step 3. Transformation Execution (30-90 Days)

From validated proof of concept to production.

- Complete application build with enterprise-grade quality

- Integration with existing systems (ERP, MES, quality)

- Comprehensive training with teams who helped build it

- Go-live support with adaptive capability for real-world adjustments

- Success metrics documentation

Outcome: Operational software running your business with measurable ROI.

Start Your Transformation Today

The warehouse managers at the Industrial Integrated Solutions Company went from skeptics to champions in 2.5 weeks. Steel Coil Processing Company eliminated Infor Syteline and implemented a customized solution to achieve perfect process fit. Both are now processing thousands of orders with complete inventory accuracy and operational confidence.

The choice is clear. The methodology is proven. The results are guaranteed.

📧 Direct Executive Contact: ricky.volz@kinetech.com

🌐 Success Stories: kinetech.com/manufacturing

.png?width=246&height=70&name=Kinetech%20PM%20246%20x%2070%20(1).png)